How To Choose The Diaphragm Pump For Your Business

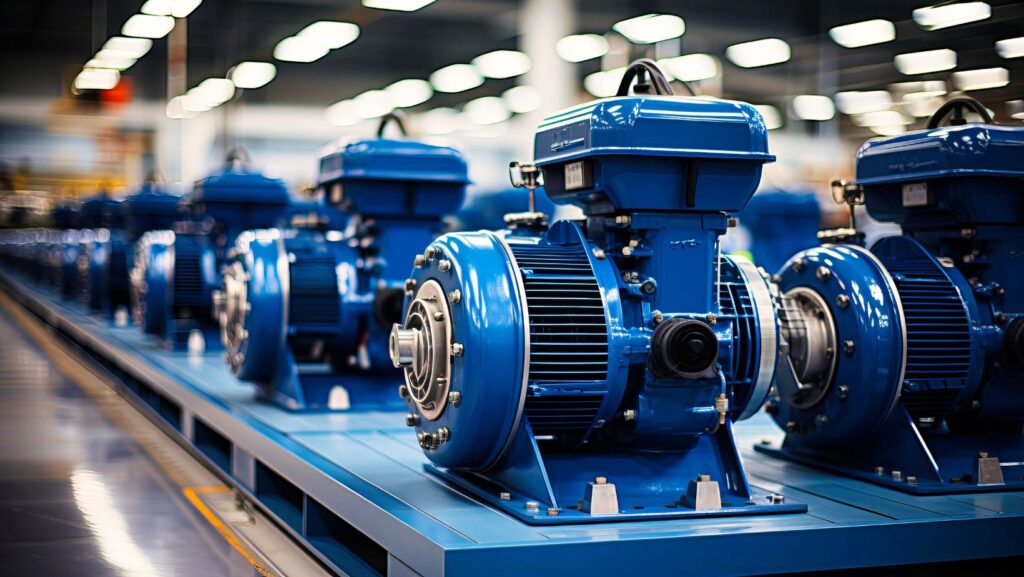

Running a business means making smart decisions, especially when it comes to the equipment you invest in. Choosing the right diaphragm pump might not be the most glamorous decision, but it’s a critical one. These pumps are workhorses in many industries, known for their versatility and reliability.

Selecting the perfect pump can streamline your operations and boost efficiency. This holds whether you’re moving abrasive fluids, managing delicate chemicals, or handling food products. But with so many options on the market, how do you pick the right one? Let’s break it down.

Why You Might Need a Diaphragm Pump

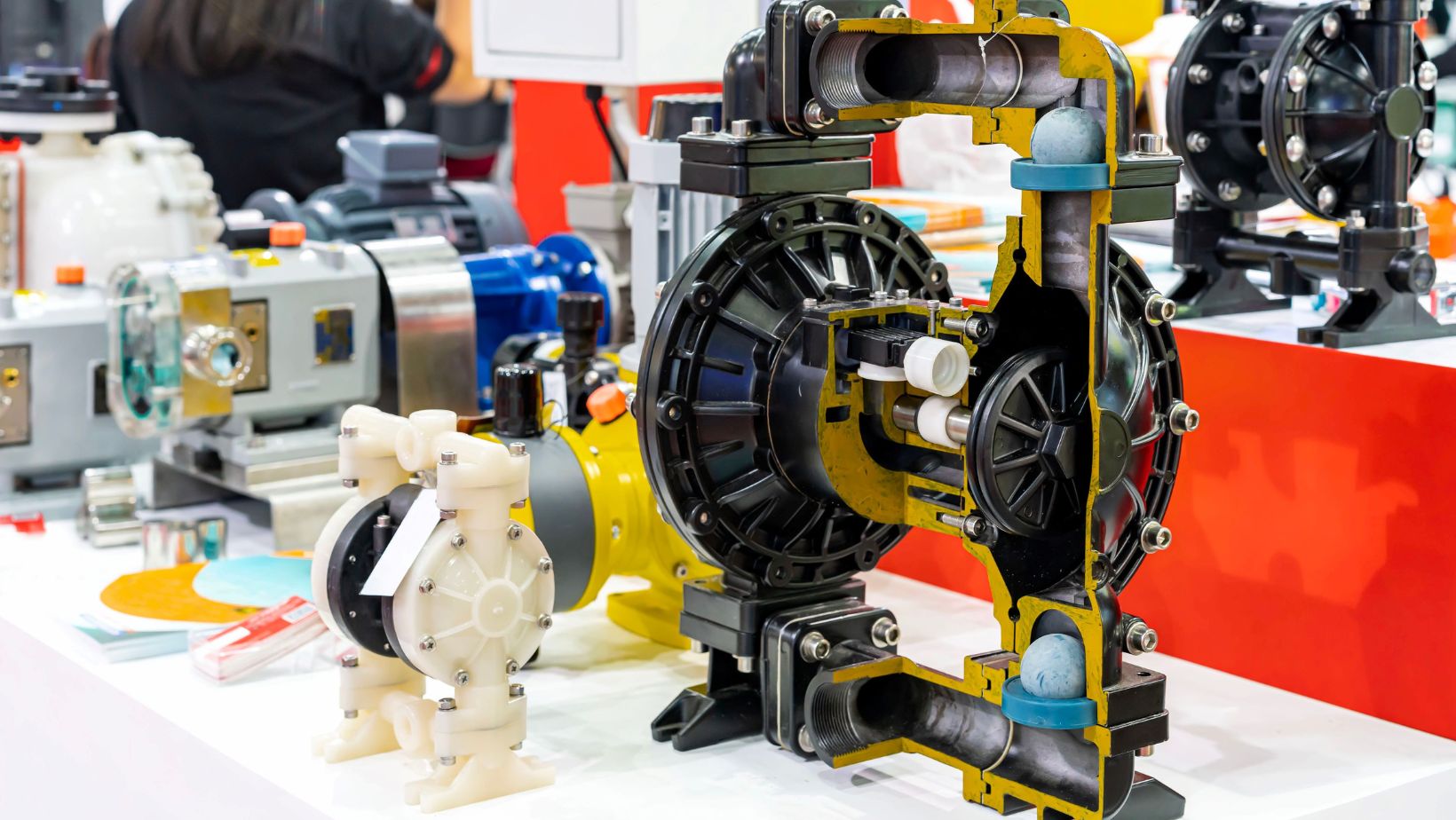

Diaphragm pumps are a type of positive displacement pump, meaning they move fluids by trapping a fixed amount and forcing it through the system. They rely on flexible diaphragms that expand and contract to create a pumping action.

What makes these pumps particularly appealing is their versatility. They can handle a wide range of materials, from thick slurries to delicate chemicals. Plus, they’re self-priming and can run dry without damage, a feature not all pumps can boast.

One popular type is the double diaphragm pump, which features two diaphragms working alternately to ensure a smooth and steady flow. These pumps shine in applications requiring precise control over flow rates, making them ideal for everything from chemical manufacturing to wastewater treatment.

Building your knowledge before making a decision is a great start. We suggest you head on to https://knf.com/en/us to discover how diaphragm pumps can help your business. Additionally, continue reading to understand how to make the right choice.

Key Factors to Consider When Choosing a Diaphragm Pump

Selecting the right diaphragm pump for your business requires a thoughtful approach. By focusing on these key aspects, you can ensure the pump you choose aligns perfectly with your operational needs.

What Will You Be Pumping?

Start by thinking about the type of fluid you’ll be working with. Diaphragm pumps are incredibly adaptable, but matching the pump’s materials to the fluid is vital. For instance:

- Abrasive fluids like slurries or liquids containing solid particles require pumps with durable materials, such as stainless steel or hard-coated aluminum.

- For chemicals, consider corrosion-resistant materials like Teflon or polypropylene.

- Food-grade applications demand pumps with materials approved by the Food and Drug Administration (FDA) to ensure safety.

If your business deals with multiple types of fluids, you’ll want a pump with interchangeable parts to adapt to different needs.

Flow Rate and Pressure Requirements

Every business has unique demands when it comes to how much fluid needs to be moved and at what speed. Flow rates are crucial in such situations. Too slow, and your operations could lag; too fast, and you might risk damaging sensitive materials.

Most AODD pumps (air-operated double diaphragm pumps) are adjustable, so you can fine-tune the flow rate to suit your application. Look for pumps with an air valve design that ensures smooth operation, preventing stalling or uneven performance. For those who may not know, these pumps are powered by compressed air, eliminating the need for an electric motor. As such, they’re safer in potentially explosive environments and reduce maintenance concerns.

Pressure is another key consideration. If your fluid needs to travel long distances or overcome high resistance, a pump with a higher pressure rating will be necessary.

Practical Tips for Choosing Your Pump

It’s time to dig into practical considerations after identifying the type of pump you need. These tips will help you find a pump that balances performance, maintenance, and efficiency for long-term success.

Match the Pump Size to Your Needs

Bigger isn’t always better when it comes to pumps. Overestimating your size needs can lead to inefficiencies and higher energy costs. On the flip side, an undersized pump might struggle to keep up. Look at your business’s typical flow and pressure requirements to find the right balance.

Think About Maintenance and Lifespan

Some pumps are easier to maintain than others. When comparing models, ask about diaphragm replacement frequency and ease of cleaning. These factors can make a big difference for industries dealing with sticky or corrosive materials.

Consider Energy Efficiency

Since compressed air powers most diaphragm pumps, efficiency becomes a critical factor. An air-efficient pump not only reduces operating costs but also minimizes your environmental footprint. Check if the pump’s air valve system can perform optimally.

In terms of structure, you choose between a single and double diaphragm pump. The former is a good choice for processing non-corrosive liquids. Those transporting potentially hazardous materials could benefit from a double diaphragm pump. At the same time, a versatile AODD pump is ideal for multiple applications.

Applications of Diaphragm Pumps Across Industries

Diaphragm pumps are true multitaskers, finding applications in industries as varied as food production, manufacturing, and environmental management. Their versatility stems from their ability to handle different materials and conditions without compromising on performance. For example:

Food and Beverage

These pumps are ideal for transferring delicate products such as sauces, syrups, or beverages like wine and beer. The gentle pumping action ensures that the texture and quality of the product remain intact while food-grade materials meet strict regulatory standards.

Chemical Processing

Chemical plants benefit immensely from the robust design of diaphragm pumps. These pumps can handle highly corrosive or reactive chemicals, such as acids, alkalis, or solvents, with ease. Precise flow control also minimizes waste, an important factor in chemical production.

Oil and Gas

This industry relies on diaphragm pumps for high-pressure applications. Examples include pumping crude oil, transferring drilling mud, or handling fuels. Oil and gas company executives often rely on a compressed air-driven AODD pump to keep operations smooth even in hazardous environments.

Construction

On construction sites, diaphragm pumps are indispensable for moving heavy, dense materials like concrete, grout, or mud. They can handle abrasive fluids without wearing even in demanding environments. For instance, when laying the foundation of a building, these pumps efficiently transfer slurry without clogging or breaking down, saving time and labor costs.

Environmental Management

Wastewater treatment plants use diaphragm pumps to move sludge, wastewater, or chemicals for neutralization. Their ability to run dry without damage and pump a mix of solids and liquids makes them perfect for this role.

From delicate beverages to abrasive slurries, diaphragm pumps deliver unmatched performance across industries. Their versatility, durability, and ability to handle diverse challenges make them an invaluable tool in countless applications. Experts estimate that the diaphragm pumps market will cumulatively grow to 6.51% from 2023 to 2030, its value reaching USD$ 11.92 billion by then.

Wrapping Up

Choosing the right diaphragm pump for your business is an investment in your operations’ efficiency and longevity. The right tool can save you time, money, and future headaches, guaranteeing that your business runs smoothly.

So, start by understanding your specific needs while leaving room for future uses. Take your time and evaluate your options carefully. It’s the only way to find a reliable solution that supports your business now and in the coming years.