How to Optimize Inventory Management During Peak Seasons

Seasonal peaks are to a business what any high-ranking holiday or special sale event is, often ushering in an upsurge of orders and demands in shipping. Laying proper plans prior to such high demand will be instrumental in ensuring that shipping operations run smoothly and in the best interest of the customer as well as being problem-free. The following are some of the key tips on how to manage shipping during seasonal peaks effectively.

Analyze Past Data and Forecast Demand

One of the major steps in preparation for seasonal peaks is to analyze past sales data and forecast demand. Go through historical data from the previous peak season and pinpoint patterns and trends, such as spikes in volume, popular products, and peak shipping times. Take this information and use it to more accurately predict forthcoming demand and plan out inventory and shipment strategies in advance. Accurate forecasting is what allows a business to predict the volume of the order and create plans for resources that are compatible with the expected increase in demand.

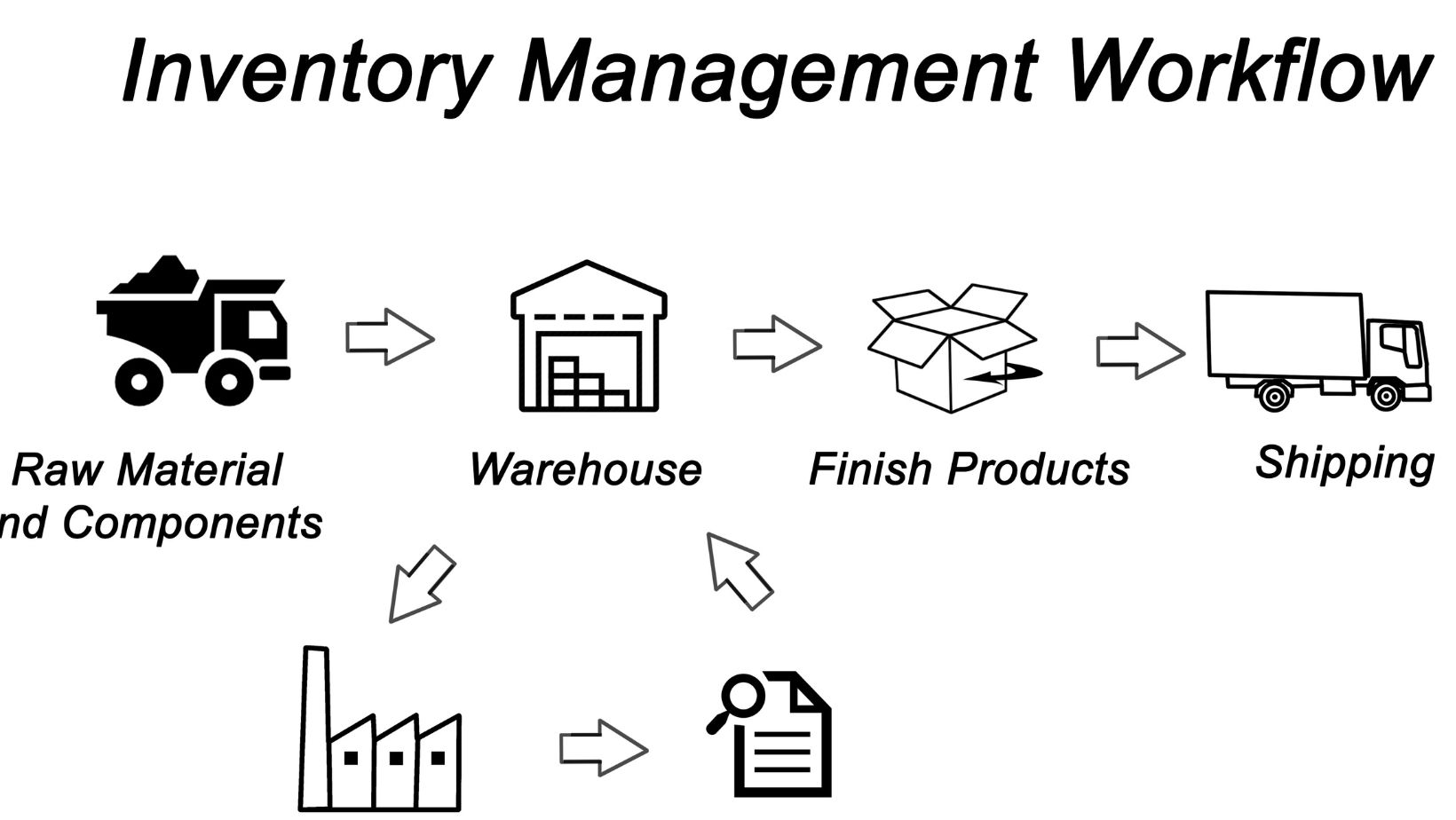

Smoothen Inventory Management

Proper inventory management is an indispensable activity during peak seasons. Make sure you have adequate inventory of fast-moving items to avoid stockouts. Consider investing in an inventory management system that provides real-time visibility into your stock levels. This gives the ability not only to track inventory but also to understand when to make a reorder. Make sure to note your safety stock levels and build in some extra to account for unexpected surges. Equally important will be the aspect of getting in touch with suppliers and manufacturers well in advance to secure essential goods and products.

Leverage Less-than-Truckload (LTL) Shipping

Less-than-Truckload (LTL) shipping can be an effective solution for managing shipping during peak periods, especially if you have smaller shipments that do not require a full truckload. LTL shipping allows you to share truck space with other shippers, reducing transportation costs and improving efficiency. This can be particularly advantageous during high-demand seasons when you need to manage multiple smaller shipments efficiently. By using LTL shipping, you can optimize your logistics operations, reduce costs, and ensure timely delivery without the need for full truckloads.

Smooth the Order Fulfillment Process

Efficiency in the order fulfillment process is a vital concern to cope with high demand periods. One will need to review and optimize fulfillment processes to ensure that they can handle large volumes of orders.

It may include re-organization of the warehouse layout for optimization of picking and packing workflows and staffing during peak times. Automation of as much as possible through the introduction of barcode scanners and sorting technologies to expedite processing times and reduce errors.

Increase Shipping Capabilities

Evaluate your shipping capability and make necessary changes that would put you in a good position to manage an increased volume from the peak season. This may include renegotiation of rates and capacity with shipping carriers, finding alternative carriers, or offering an extended range of shipping options. Provide a multi-carrier strategy to ensure flexibility and reduce the risks associated with dependence on one carrier. Consider expedited shipping as an option to offer faster delivery to those customers who need it.

Improve Communication with Shipping Partners

Good communication with your shipping partners during peak periods is highly important. Forecasts and peak season plans should be shared with the carriers so they can be prepared for the excess traffic. Clearly define lines of communication for timely updates on any status, delays, or anything very important concerning the shipments. Building good working relationships with your shipping partners can reap rewards in prioritizing your shipments and supporting you when you need it.

Provide Order Tracking, Customer Service

Tracking capabilities for orders and exceptional customer service will be the icing on the cake for the customer experience this season. Avail tracking systems so that orders can be tracked in real time. Also, train your customer service to answer all queries, resolve issues regarding orders, and process returns promptly. Updates on delays or changes in the delivery schedule will not only manage expectations but also keep customers satisfied.

Prepare for Returns and Exchanges

Return and exchange management is about as important as outgoing shipment management. Create a returns process that can handle easily and transparently the increased volumes at peak seasons.

Communicate your returns policy clearly to customers, making the process simple. Pre-paid return labels or easy return options help to provide an improved customer experience that will aid in smoothing the process of managing returns.

Assess and Adapt Performance after Peak

Once the peak season is done and dusted, take a look at how well you performed to identify areas for improvement. Check some of the key metrics in terms of order accuracy, shipping times, and customer satisfaction to see how all the strategies went down. Secondly, get feedback from customers and shipping partners about the issues that were faced during this period. This will be important in adjusting for improvement next time around.

Conclusion

This will indeed be smooth shipping, very well planned and executed to handle the peak season’s increased demand. A business may manage high-demand periods through various activities: analysis of past data, optimization of inventory, streamlining of order fulfillment, enhancement of shipping capabilities, and effective communication with shipping partners. Additionally, robust tracking systems, preparation for returns, and performance evaluation after the peak will be other contributing factors to a successful peak season. Companies will, therefore, be able to deliver demand, reduce disruptions, and take advantage of the seasonal peaks by implementing these strategies.